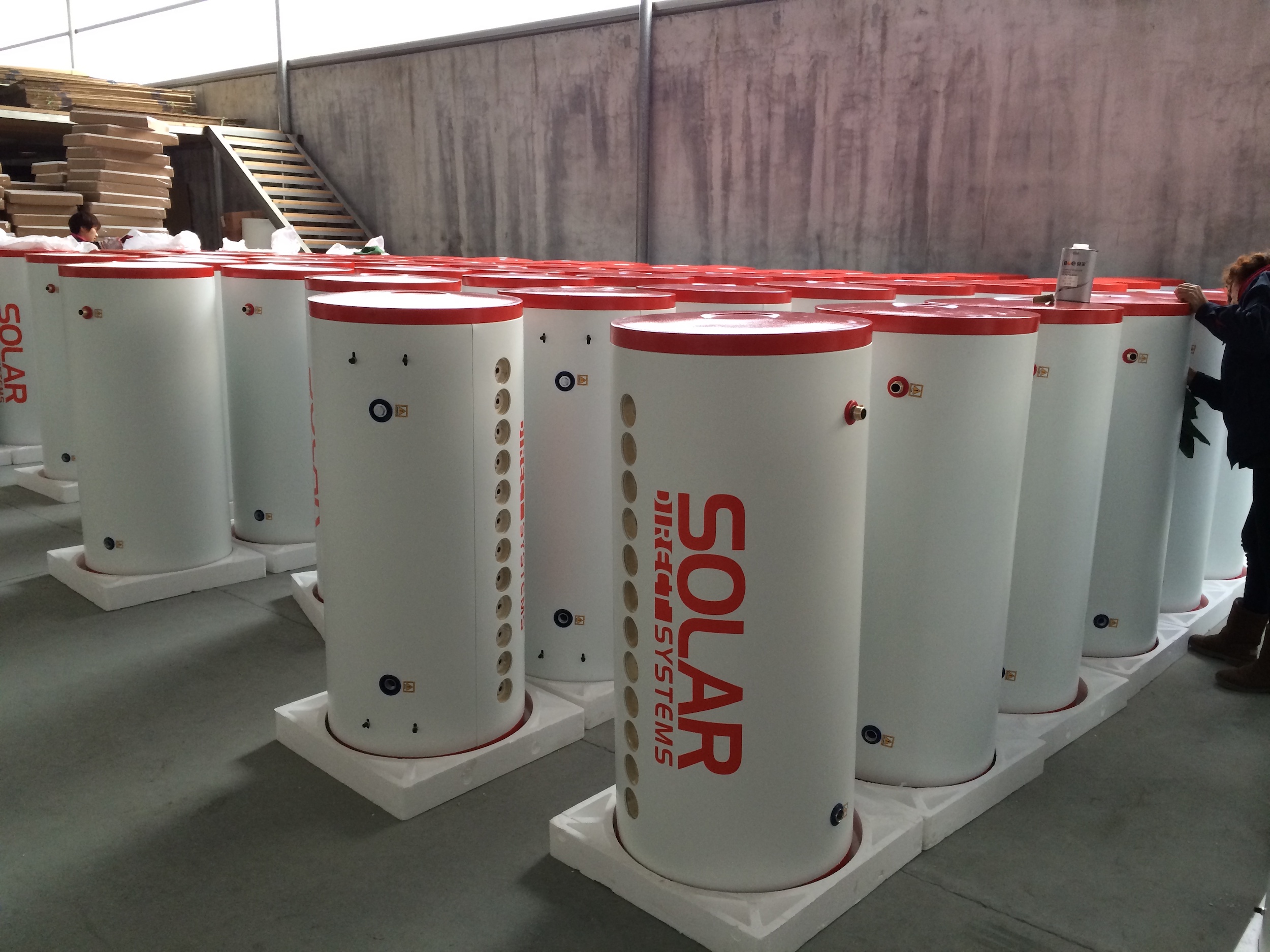

Enamel Tank production Line

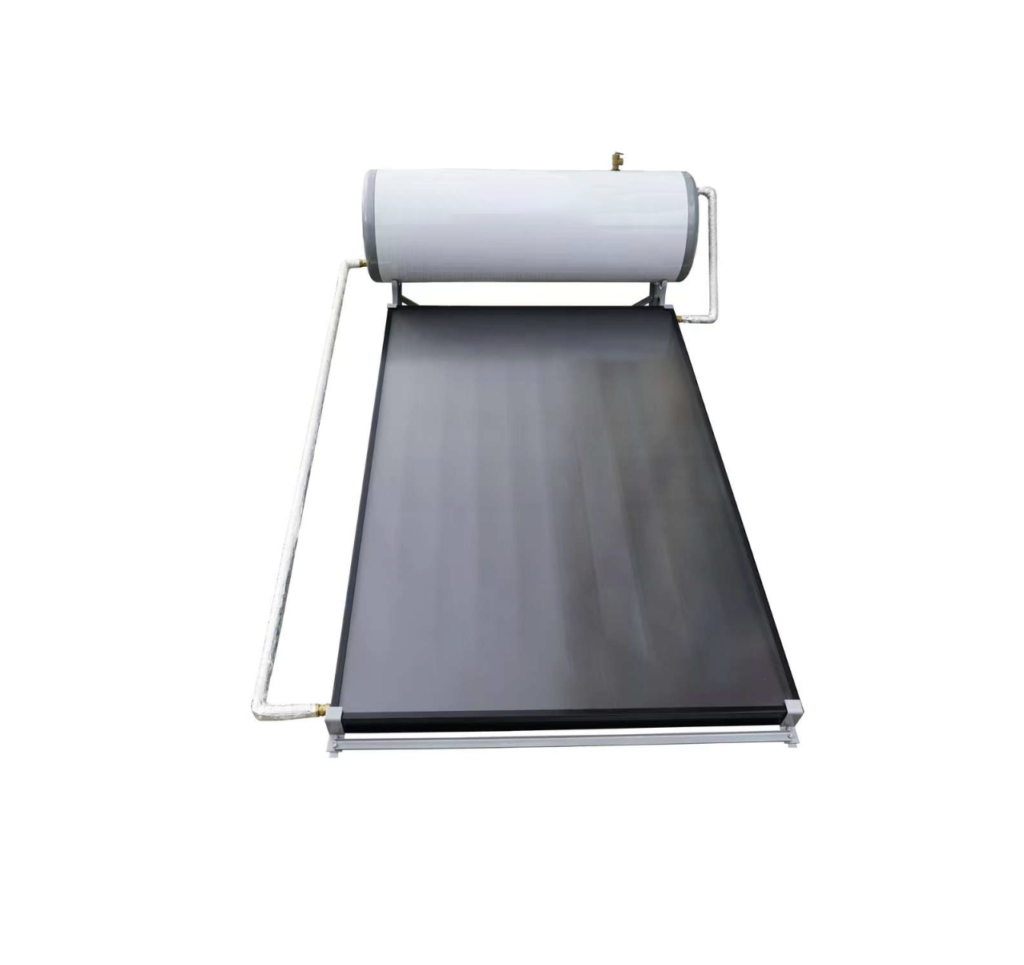

A solar flat plate collector is a device used to collect solar energy and convert it into usable heat. It is one of the most widely used systems for solar heating and hot water.

Working Principle: The flat plate collector works on the principle of absorption, conduction, and radiation. The collector consists of a flat plate covered with a dark absorbing material, which absorbs solar radiation and converts it into heat. This heat is then transferred to a fluid, usually water or air, that flows through the collector. The heat is then transferred to the storage tank or hot water system through a heat exchanger.

Advantages:

Efficient: The flat plate collector is an efficient way to collect solar energy and convert it into usable heat. It can be designed to meet specific energy requirements, making it an ideal option for residential and commercial applications.

Low Maintenance: The flat plate collector is simple in design and requires very little maintenance. The absence of moving parts makes it durable and long-lasting.

Affordable: The flat plate collector is an affordable option for solar heating and hot water systems. The materials used in its construction are readily available and cost-effective, making it accessible to a wider range of people.

Easy Installation: The flat plate collector is easy to install and can be integrated into existing heating and hot water systems. This makes it a popular choice for retrofitting existing homes and buildings.

Environmentally Friendly: The flat plate collector is an environmentally friendly option for heating and hot water. It reduces the reliance on fossil fuels and helps to reduce greenhouse gas emissions.

- Solar Brackets or Frame for solar water heaters come in two popular angles: 27 degrees and 45 degrees.

- The South American market mainly uses aluminum and stainless steel brackets, while the Indian and African markets commonly use galvanized steel in different colors.

- The material used for tank support is also important and can vary from stainless steel pipes to normal types. The tank supporter is selected based on the tank diameter, with a common outer tank diameter of 480mm.All depends on customer’s requirements.

Solar Thermal Panel Heat Pipe Collector

Types of Heat Pipe Solar Collectors: Heat pipe solar collectors come in different tube counts including 12 tubes, 15 tubes, 18 tubes, 20 tubes, 24 tubes, and 30 tubes. They are used for pressurized tank applications and are either evacuated tube heat pipe collectors or flat plate solar collectors.

Heat Pipe Design: Heat pipes can have either a single or double heat pipe design, which is chosen based on the customer’s heat performance requirements. The condenser can also be varied.

Heat Collection: The heat pipe evacuated tube has an aluminum fin that conducts the heat collected from the sun’s energy. The typical size used is 58x1800mm.

Functionality: The purpose of a heat pipe solar collector is to absorb and transfer solar energy for various heating applications. It works by using vacuum-sealed tubes to capture the sun’s energy and transfer it to a heat exchanger, where it is then used to heat water or other fluid.

Efficiency: Heat pipe solar collectors are known for their high thermal efficiency and quick heat transfer capabilities. This is due to the heat pipe’s ability to rapidly transfer heat from the sun-facing surface of the collector to the heat exchanger.

Durability: With proper maintenance, heat pipe solar collectors are designed to last for many years. The vacuum-sealed tubes protect the collector from outdoor elements and the aluminum fin provides a durable surface for heat transfer.

Widely Used: Heat pipe solar collectors are widely used for residential and commercial hot water systems, space heating, and industrial process heating applications. Their high efficiency, durability, and versatility make them a popular choice for many energy-saving and sustainability projects.

Solar Commercial Collector is designed for commercial applications such as hotels, resorts, hospitals, and schools where hot water demand is high. The vacuum tube technology provides excellent heat transfer and the stainless steel construction ensures durability and longevity. The large water tank provides ample storage for hot water and the solar controller ensures that the system operates efficiently. The series connection of the collectors allows for the system to be easily expanded to meet the growing hot water demand. Overall, the solar commercial collector is a reliable and efficient solution for commercial hot water needs.

Solar Non-Pressurized Production Line

We have a colorful outer tank and a Stainless Steel outer tank, an inner tank 0.4mm/0.5mm thickness usually. But we also can design based on your requirements. Please send us mail at [email protected] to get full details

Enamel Tank for solar water heater

An enamel tank for a solar water heater has several advantages over other types of tanks, including:

Durability: Enamel is a strong, hard material that is resistant to corrosion and wear. This means that an enamel tank for a solar water heater can last for many years without needing to be replaced.

Hygiene: Enamel is a non-porous material, which means it doesn’t absorb impurities, bacteria, or other contaminants. This makes it an ideal choice for a water storage tank, as it helps to keep the water clean and safe to use.

Insulation: Enamel is a good insulator, which means it can help to keep the water in the tank warm for longer periods of time. This is particularly useful for solar water heaters, as it can help to ensure that there is always hot water available, even on cloudy days.

The market for enamel tanks for solar water heaters is growing, as more and more people are looking for sustainable and cost-effective ways to heat their water. This is especially true in areas where there is a lot of sun, as solar water heaters are most effective in these locations.

Overall, an enamel tank for a solar water heater is a good option for a long-lasting, hygienic, and well-insulated water storage tank that can be used in a variety of different settings.

The capacity of an enamel tank for a solar water heater will depend on the specific needs of the household or building it will be used. Generally speaking, the larger the tank, the more hot water it will be able to store. However, it is also important to consider the size of the solar collector and the amount of sunlight that is available in the area.

For a typical family home, a tank with a capacity of 200 to 300 liters is usually sufficient. This will provide enough hot water for daily use, such as showering, washing dishes, and doing laundry. For larger households or commercial buildings, a tank with a capacity of 500 to 1000 liters may be more appropriate.

It’s always a good idea to consult with a professional solar water heater installer to determine the appropriate size of tank for your specific needs. They will take into account the number of people living in the home, their hot water usage patterns, and the available space for the tank, to determine the most suitable capacity for you.

How the enamel tank production line work

Real Enamel Tank Production

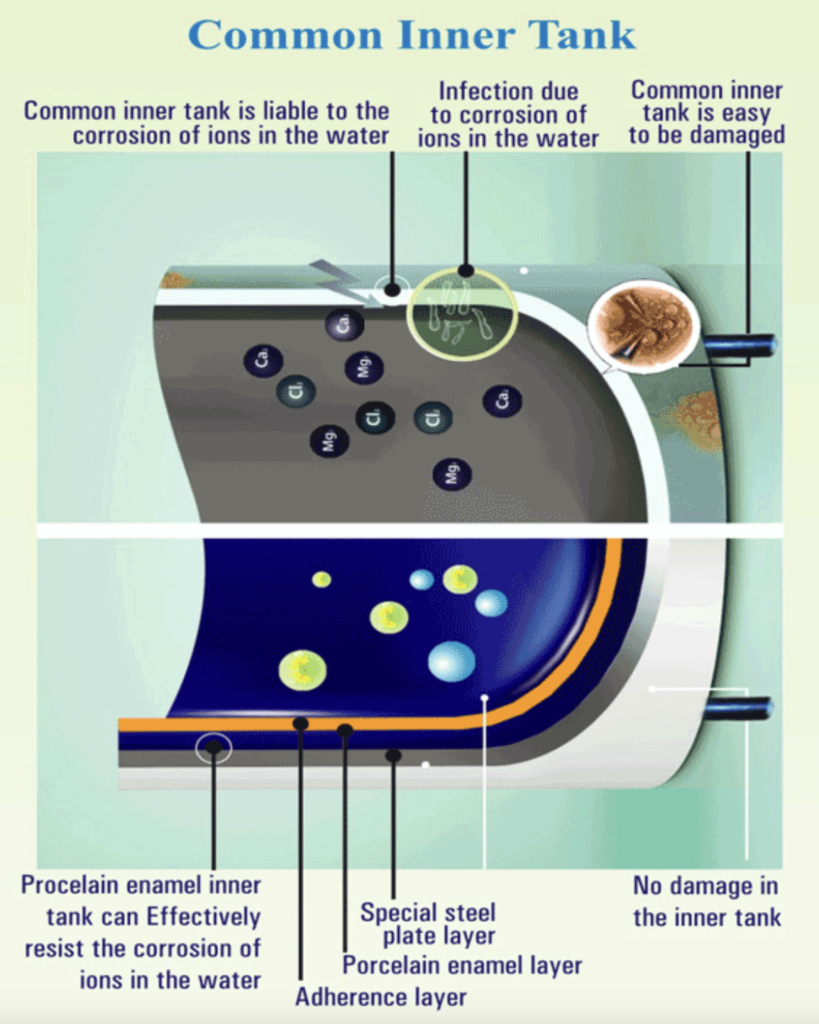

Enamel Tank Water Heater Corrosion Protection Technology

Porcelain Enamel Tank — is a trusted & proven technology for inner tanks of water heaters. Used widely across the world, it is ideal for long life & trouble-free performance in all kinds of water. More than 95% of water heaters produced worldwide are with enamel tanks. Excellent corrosion protection due to the fusion of glass layer to metal.

Porcelain or Glass Enameled Tank Advantages

- Makes the system suitable for all kinds of water.

- No scaling or dirt deposits occur inside the tank.

- Since glass is a good insulator of heat, water remains hot for longer

- Acid, alkali, corrosion resistance.

- No leakage, no seepage, and good sealing performance.

- Hot water is better than other tanks. (requires heat-resistant strips)

- The interior of the enamel tank is smooth and easy to clean.

- Gives you clean and hygienic water for bathing purposes.

- Ensures no Particle reacts with the tank

- High-quality international standard glass coating keeps the tank free of rust and corrosion

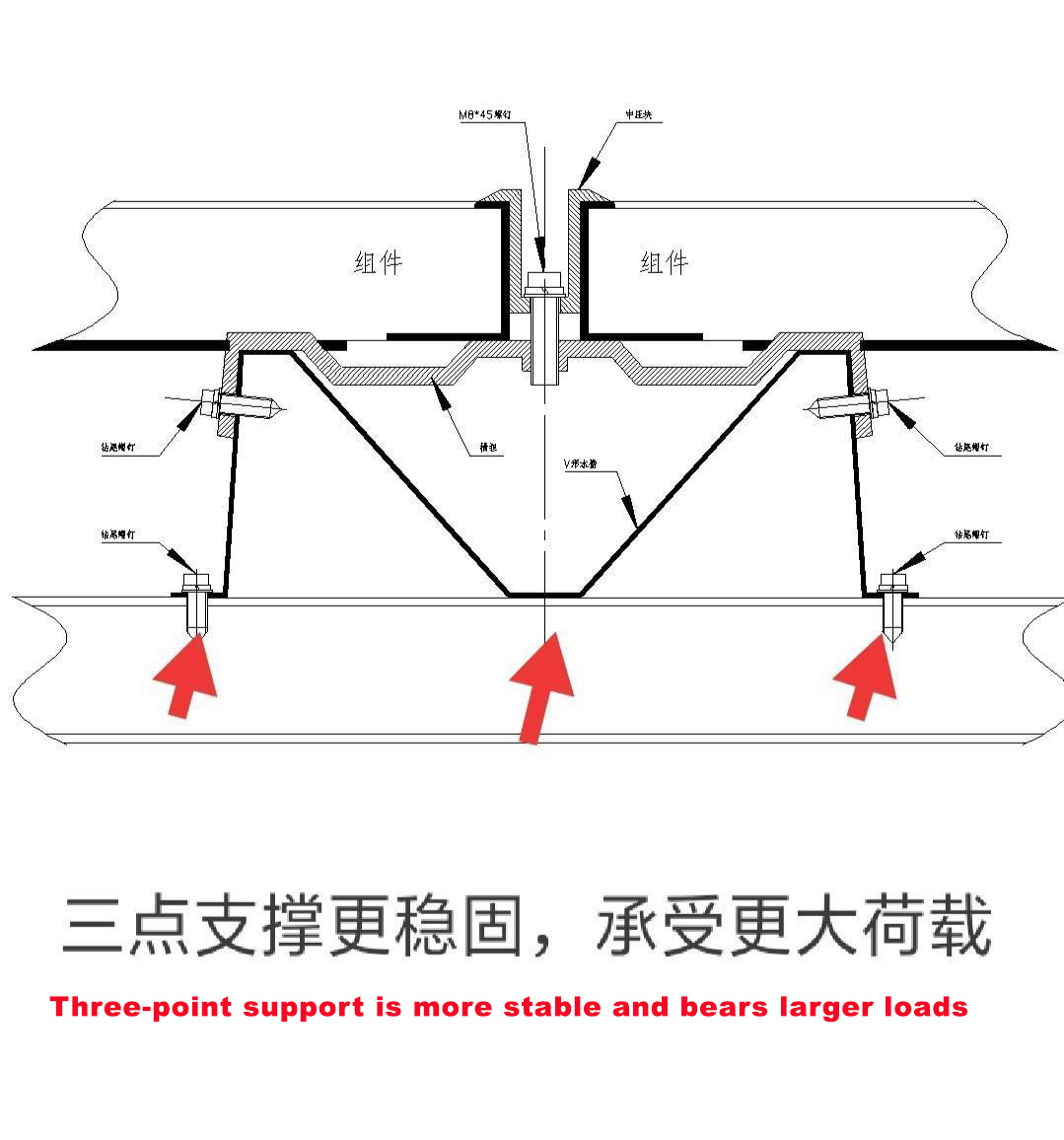

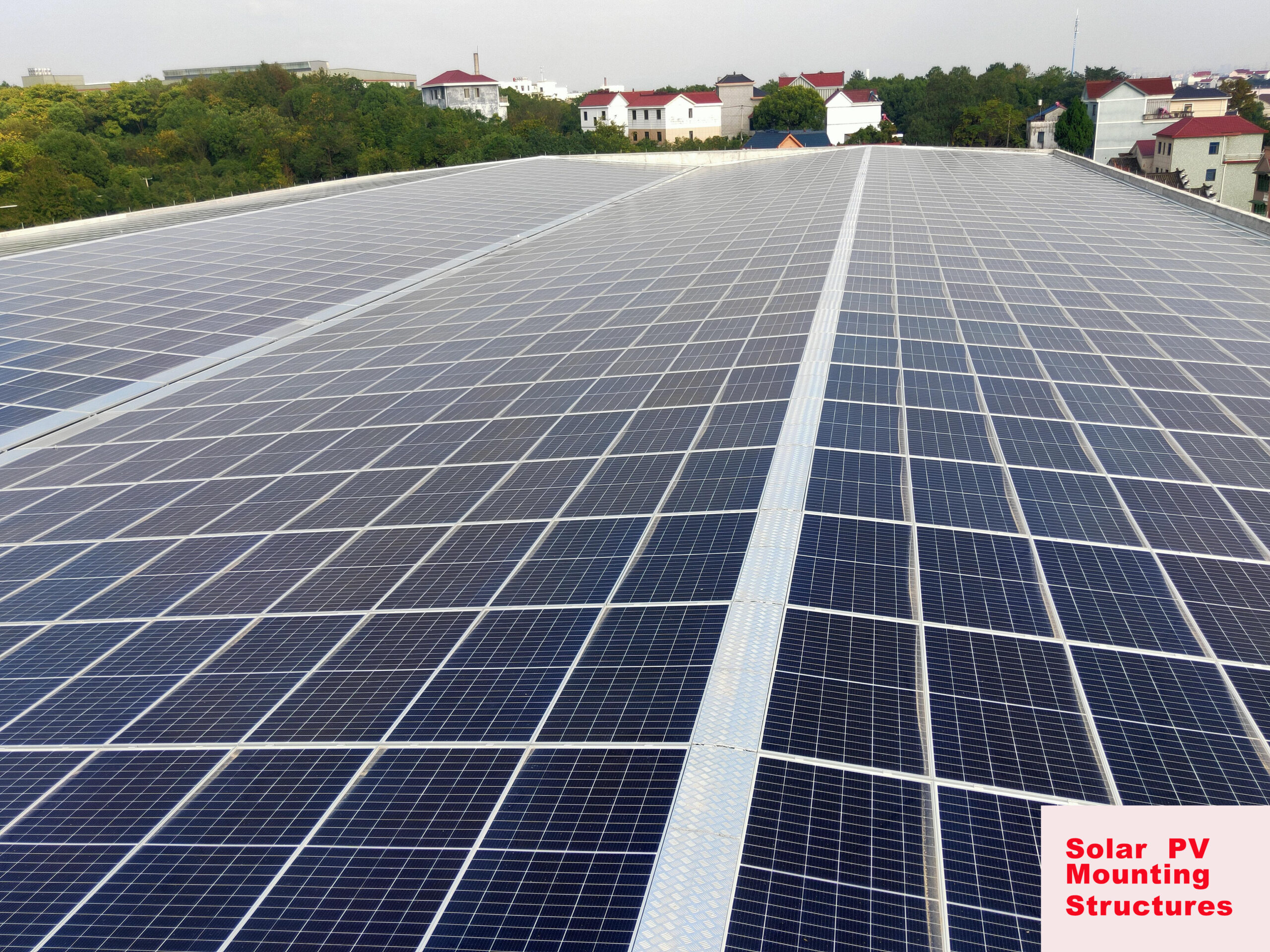

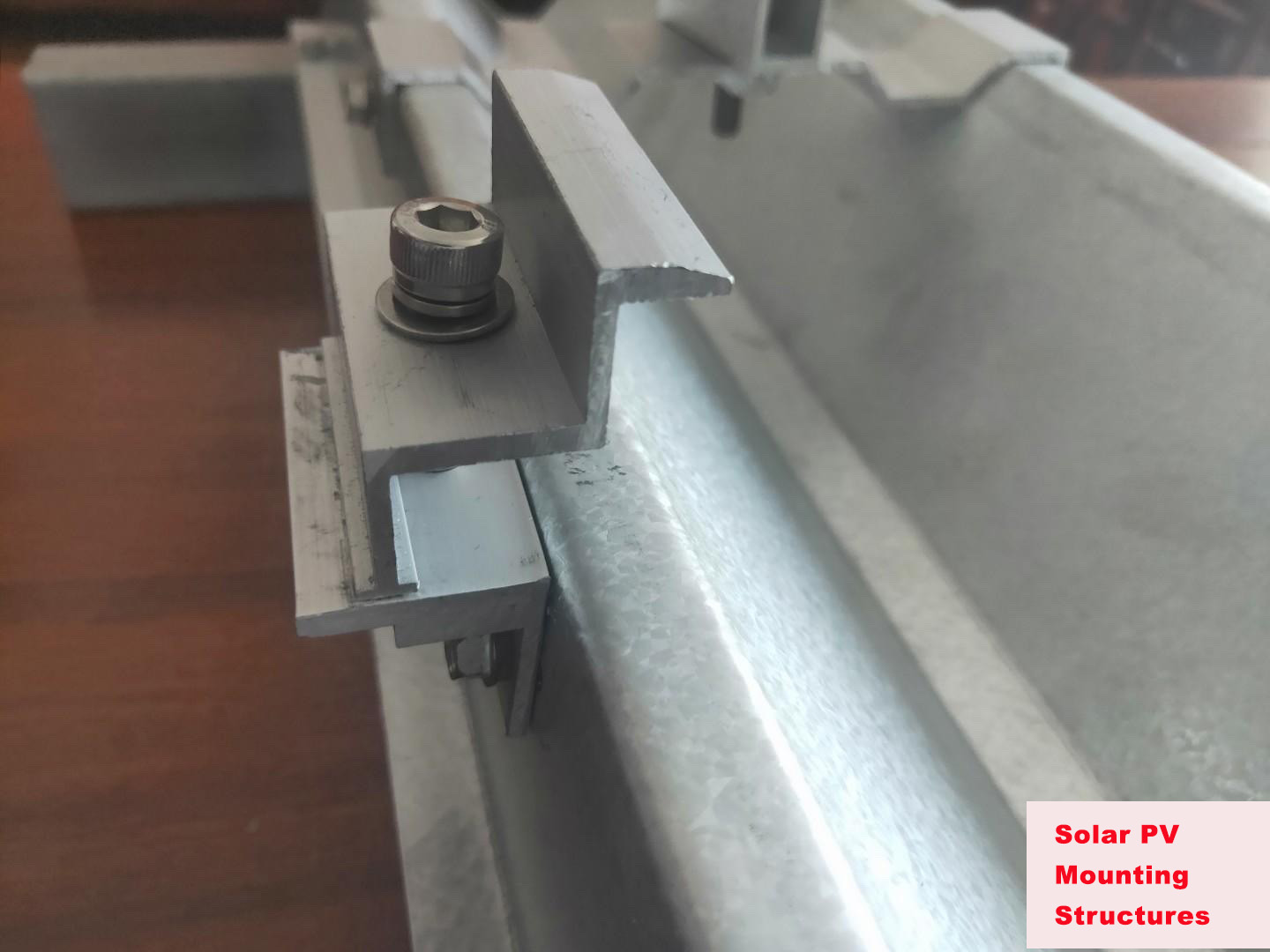

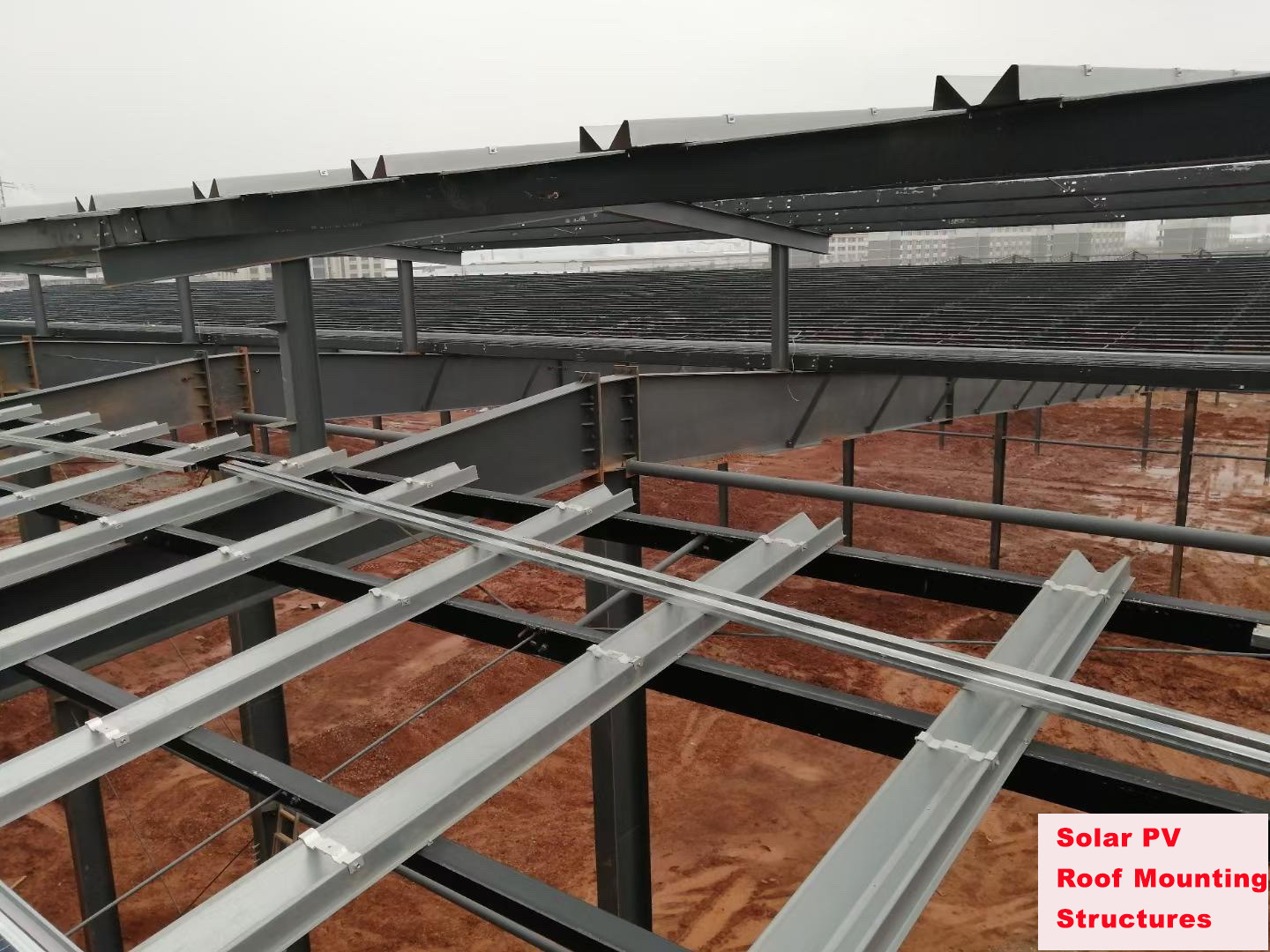

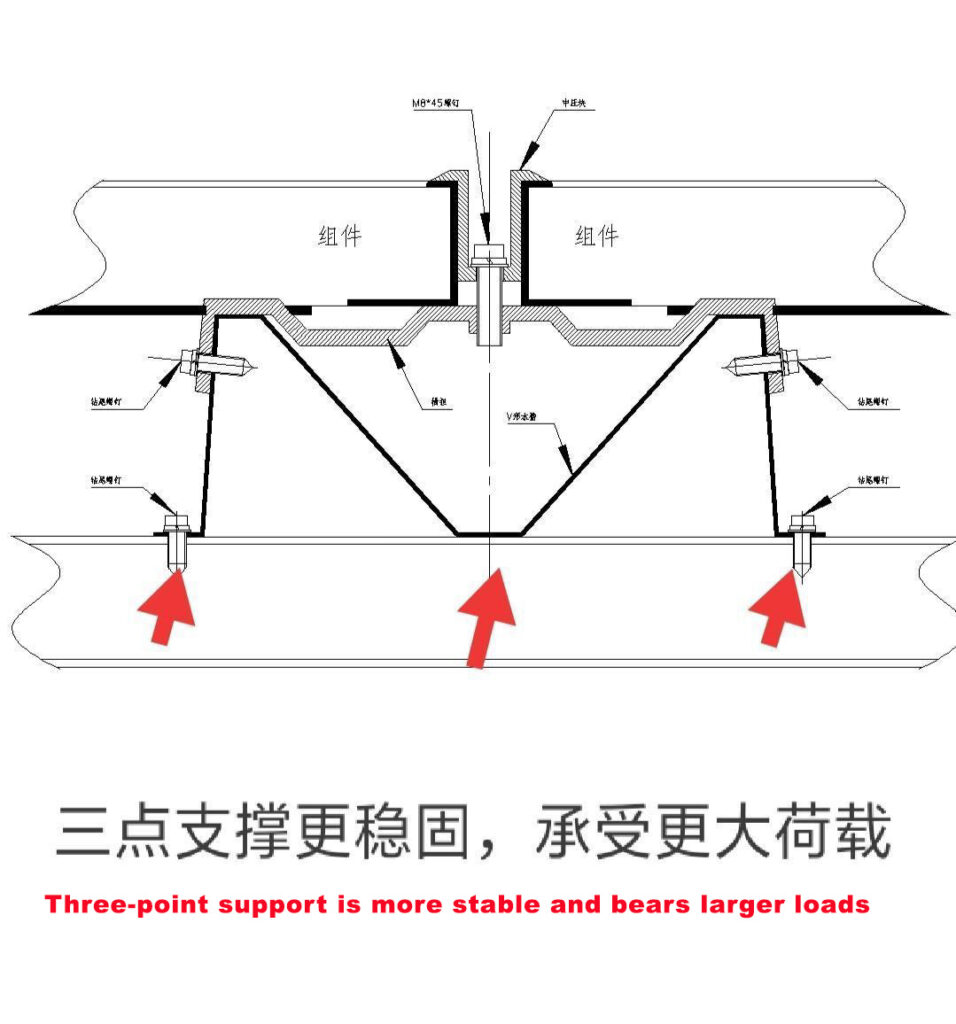

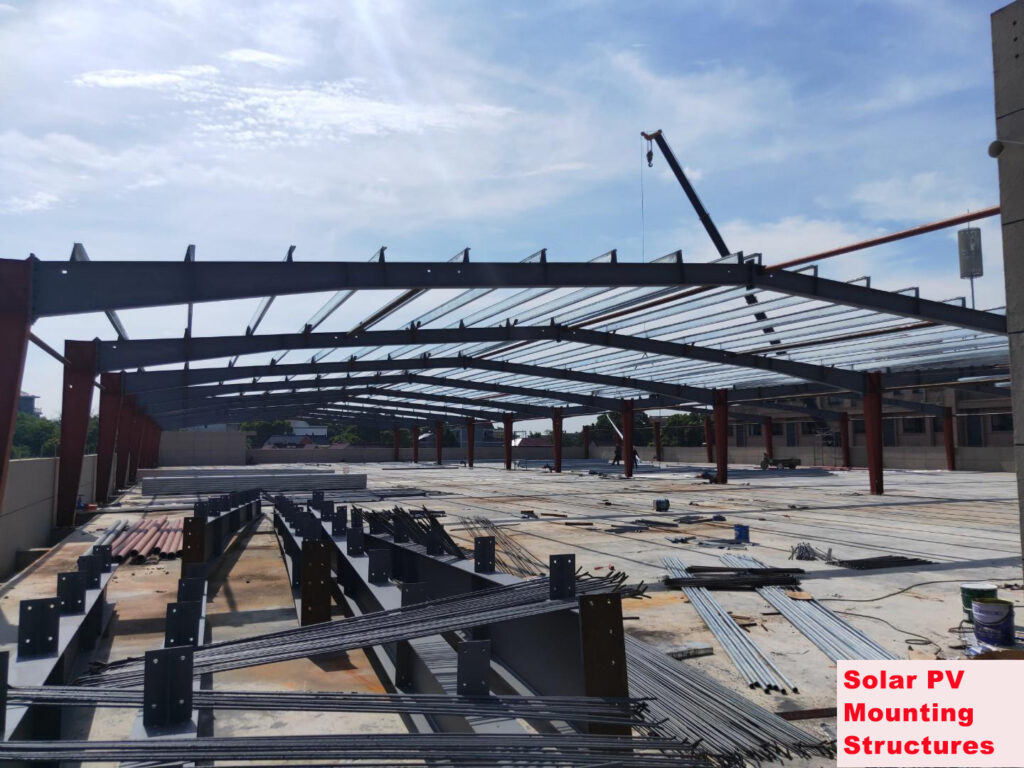

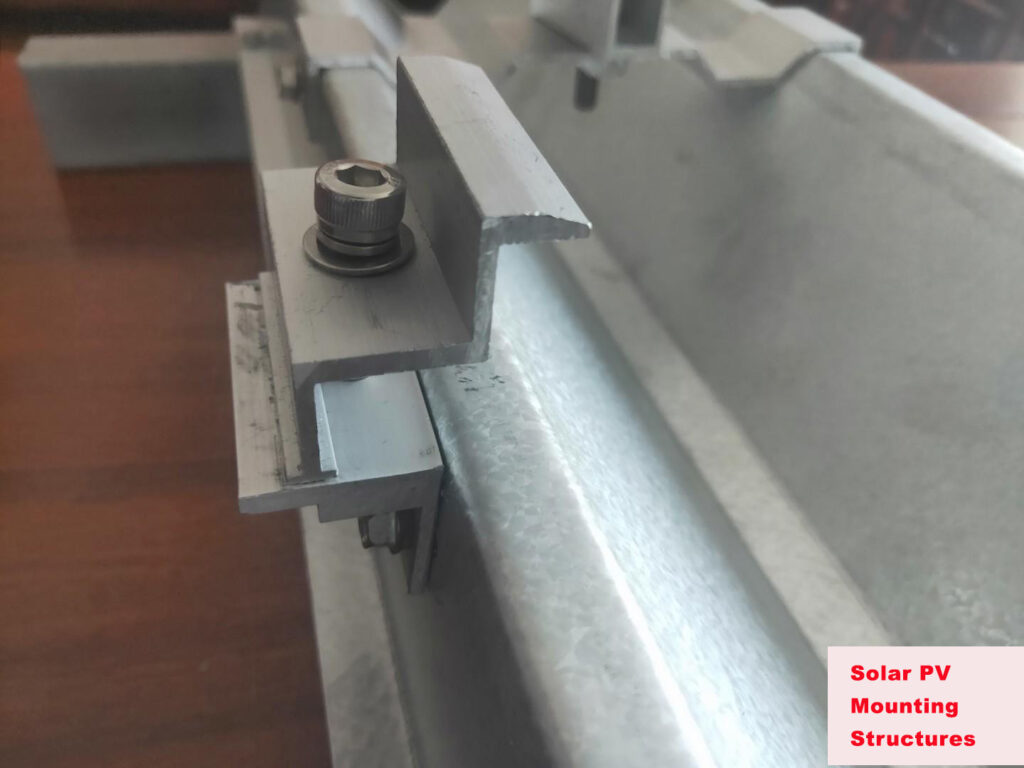

Solar Photovoltaic(PV) Mounting Structure

Technical Information

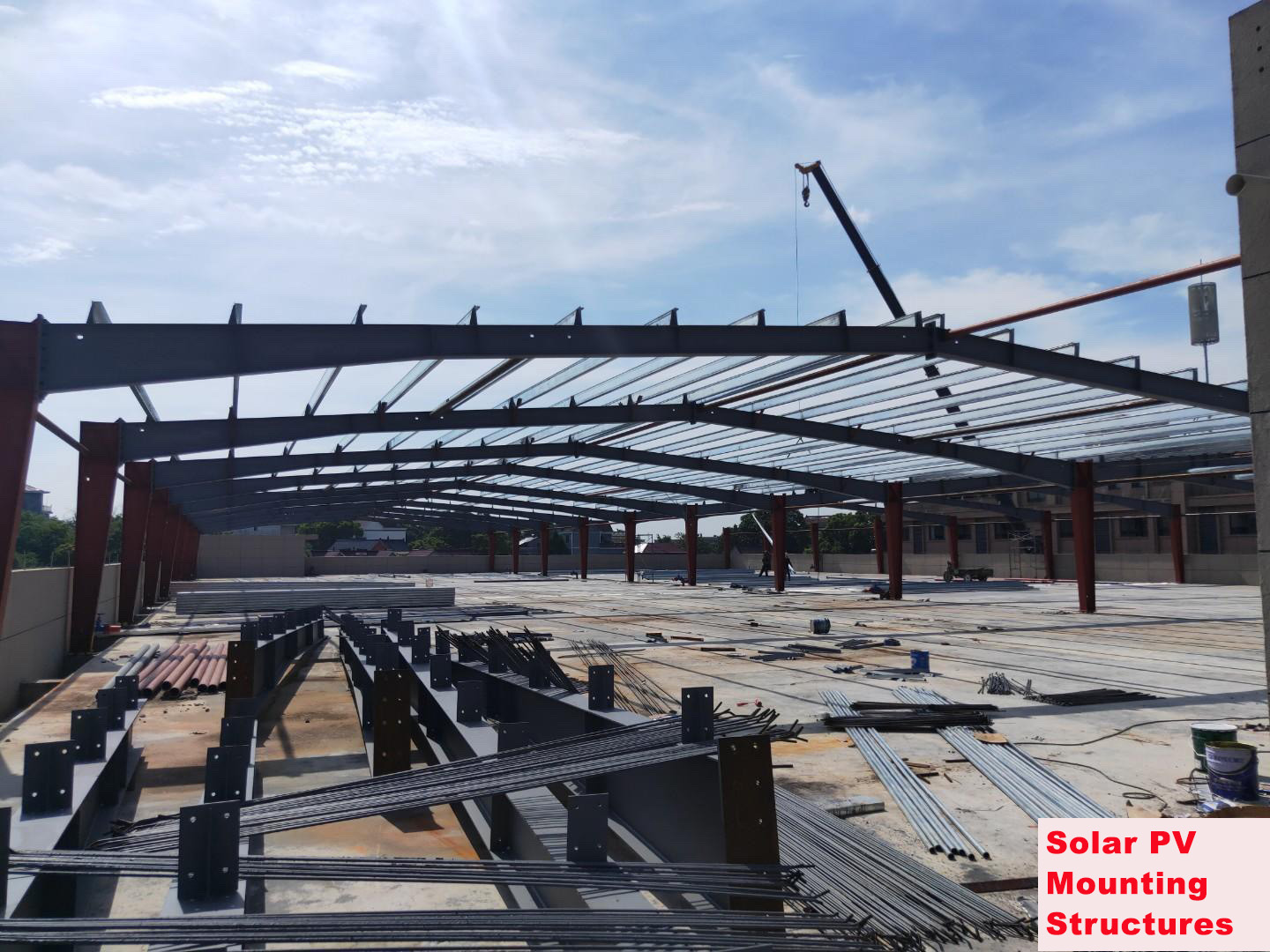

- Installation Site: Flat Roof or pitched roof

- Material: Aluminum 6005-T5 & SUS 304

- Max Wind Speed: <60m / s

- Max Snow Load: <1.4 KN / M2

- Fixed Angle: 5°~ 30°

- Warranties: 12 Years

Features & Benefits

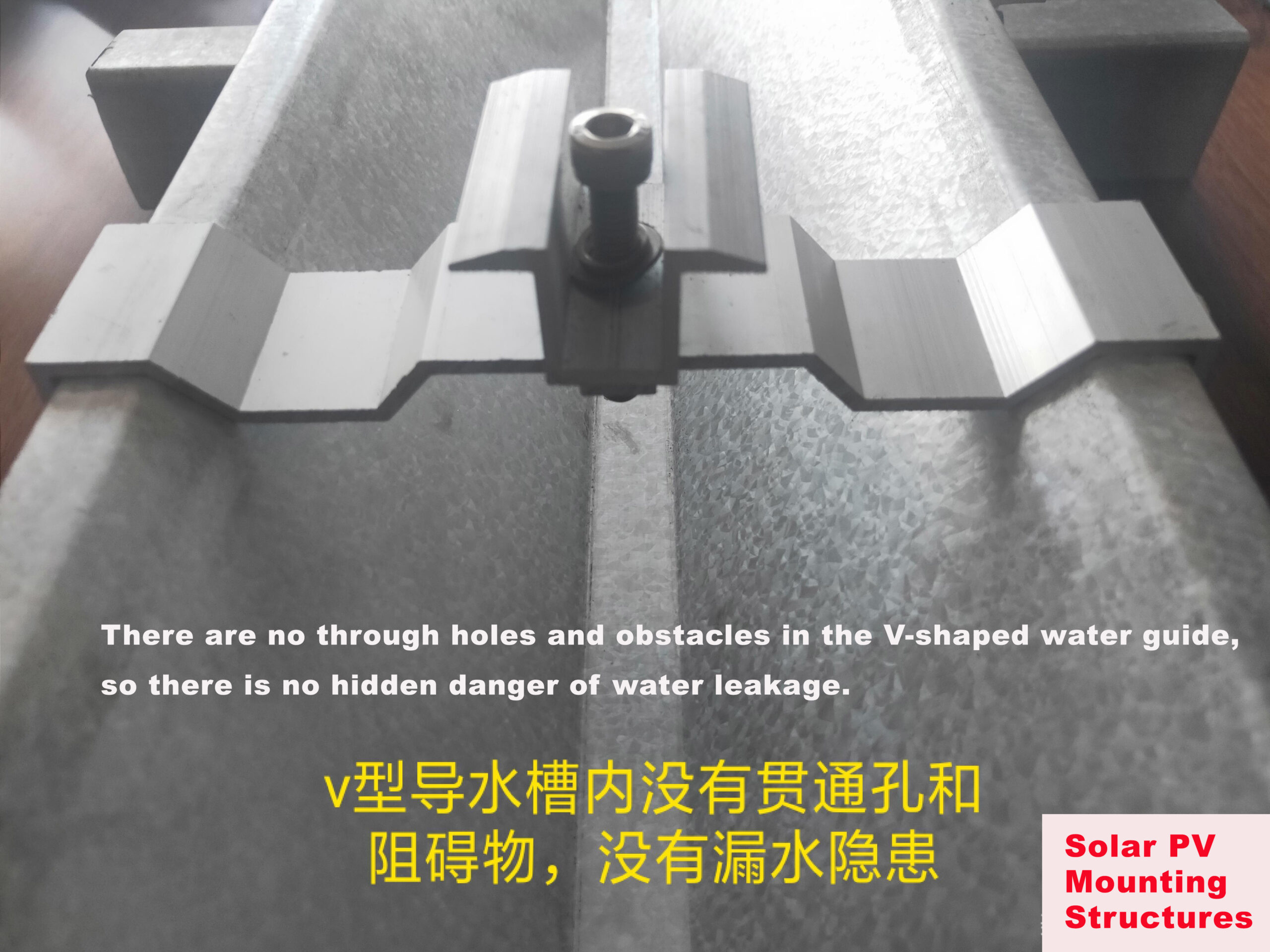

a) Non-Penetrating to roof

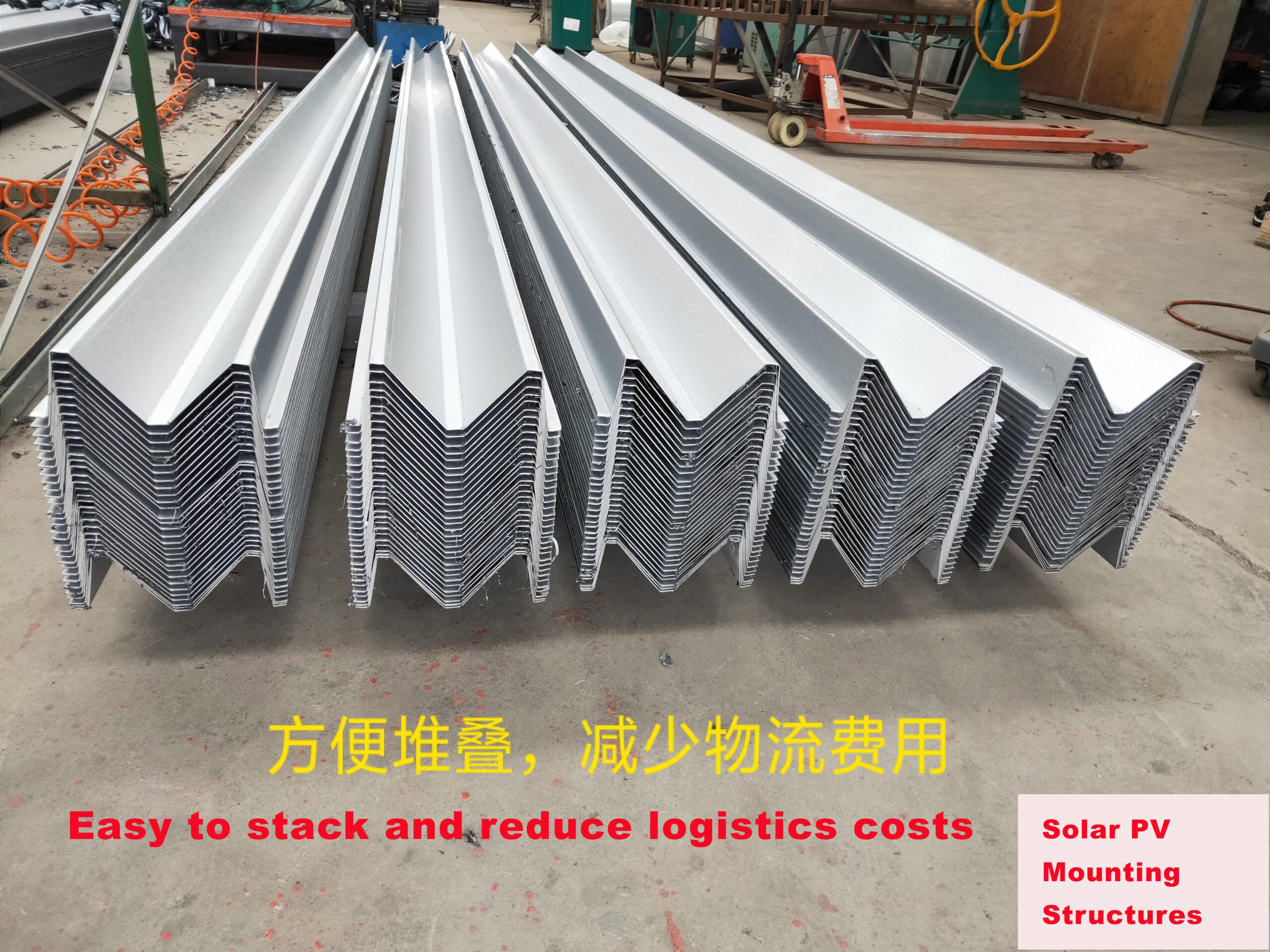

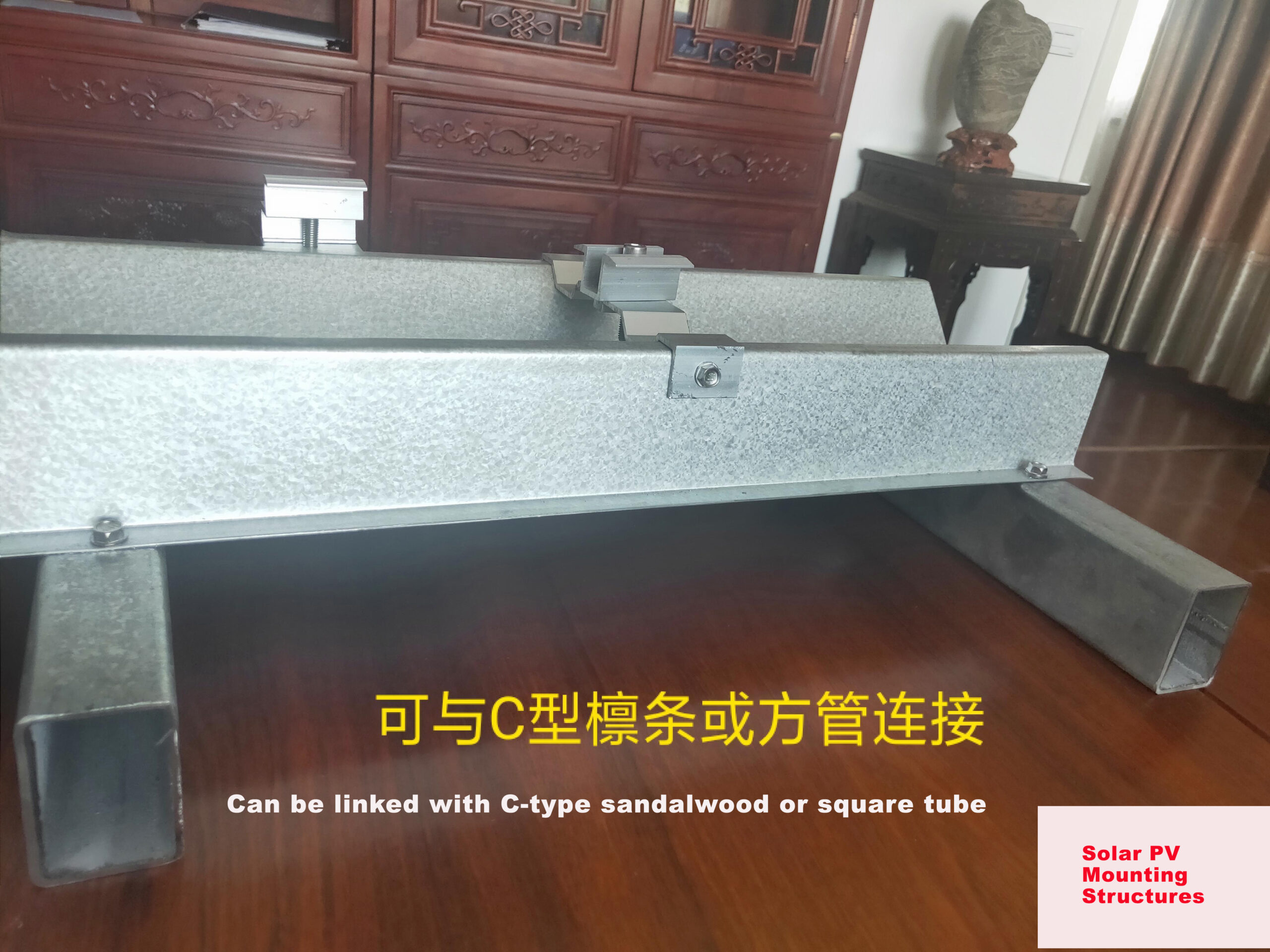

b) Pre-assembled parts for simple and fast installation

c) Minimize roof space limitation

d) Fixed angle or adjustable angle is both acceptable

e) Rail-less

f) Suitable for all orientations installation

g) Optimize high-power production

|

Install Site: |

Installation Site: Flat Roof or Pitched Roof |

| Module Orientation: | Portrait or Landscape |

| Max. Wind Speed: | ≤60m/s |

| Max. Snow Load: | ≤1.4kn/m2 |

| Fixed Angle: | 5°-60° |

| Anti-corrosive Treatment: | Shot Blasting or Anodize |

| Adjustable Angle: | 5°-15°, 15°-30°, 30°-60° |

| Anti-corrosion: |

Anodized Aluminum 6005-T5 & Stainless Steel 304 |

| Warranties: | 12 years warranties & 20 years service life |